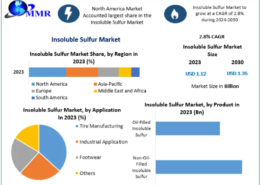

Global Insoluble Sulfur Market Outlook 2024-2030

The Global Insoluble Sulfur Market is projected to reach USD 1.35 billion by 2030, growing at a CAGR of 2.8% during the forecast period 2024-2030. This growth is largely driven by rising demand from the rubber and tire manufacturing industries, along with increasing applications in industrial processes, cables, pipelines, and footwear manufacturing.

Market Overview

Insoluble sulfur is a key vulcanizing agent used in rubber production, enhancing elasticity, strength, and thermal stability. It plays a critical role in converting raw rubber into durable finished products under high heat. Beyond tires, it is used in wire and cable shielding materials, industrial applications, and other specialty products.

The market benefits from rising industrialization, expanding automotive manufacturing, and increasing global vehicle production, which collectively boost the demand for rubber-based products. Moreover, advancements in high-dispersion and high-stability sulfur grades offer superior performance, driving adoption among manufacturers.

Secure your sample copy of the report today:https://www.maximizemarketresearch.com/request-sample/99386/

Market Dynamics

Drivers:

- Increasing global tire production due to higher automotive sales.

- Rising industrial applications in wire, cable, and pipeline manufacturing.

- Enhanced material performance with high-dispersion and high-stability grades improving rubber quality.

Restraints:

- Fluctuating raw material prices and disrupted supply chains, especially during global crises like the COVID-19 pandemic.

- Limited availability of high-purity grades in certain regions, posing challenges for manufacturers.

Segment Analysis

By Grade:

- Regular Grade: Dominant, accounting for over 64% of the market in 2023. Economical and widely used in standard rubber manufacturing without additives.

- High Dispersion Grade: Gaining traction due to superior dispersibility and performance in complex rubber compounds.

- High Stability Grade: Expected to register the highest CAGR, offering high thermal stability and better compatibility with performance-enhancing additives.

By Application:

- Tire Manufacturing: Largest consumer segment, driven by the automotive sector.

- Industrial Applications: Includes wire, cable, and pipeline production.

- Footwear: Specialty rubber products for durable footwear.

- Others: Includes adhesives, coatings, and niche rubber products.

By Product Type:

- Non-Oil-Filled Insoluble Sulfur

- Oil-Filled Insoluble Sulfur

Regional Insights

Asia Pacific dominates the market, accounting for nearly 48% of global revenue in 2023, driven by:

- Rapid growth of rubber manufacturing industries in China, India, Japan, and South Korea.

- Low-cost skilled labor, favorable regulations, and growing automotive production.

- China’s role as a leading rubber exporter across Asia further boosts market demand.

North America and Europe maintain steady demand due to established industrial sectors and high standards for rubber processing. Emerging markets in Middle East, Africa, and South America are gradually increasing consumption as industrialization and automotive production expand.

Secure your sample copy of the report today:https://www.maximizemarketresearch.com/request-sample/99386/

Competitive Landscape

Key players dominate through innovation, strategic partnerships, and global distribution. Major companies include:

- Eastman Chemical Company

- LIONS INDUSTRIES

- Nynas AB

- Oriental Carbon & Chemicals Limited

- Shanghai Shangyi Chemical Technology Company

- SHIKOKU CHEMICALS CORPORATION

- China Sunsine Chemical Holdings Limited

- Grupa Azoty

- Henan Kailun Chemical Co., Ltd.

- Schill + Seilacher “Struktol” GmbH

Other notable players include Kumho Petrochemical, LANXESS, Sanshin Chemical Industry, and Zhejiang NetSun Co., Ltd.

These companies focus on R&D, high-performance product development, and expanding regional presence to maintain leadership.

Recent Developments

- September 2021: Tommie Ibert launched a new video extensometer in Nynas Rubber Compounding Lab, enhancing testing capabilities for rubber products.

- Continuous development of high-dispersion and high-stability grades is improving thermal and mechanical performance of rubber, increasing adoption across tire and industrial sectors.

Market Outlook

The Insoluble Sulfur Market is poised for steady growth through 2030, driven by expanding automotive and industrial sectors, technological advancements in sulfur grades, and rising demand for durable rubber products. Manufacturers focusing on quality, efficiency, and high-performance grades are expected to gain a competitive edge in this evolving market.